Concrete is basically a mixture of aggregates and paste.

The aggregates are sand and gravel or crushed stone; the paste is water and cement. Portland cement is not a brand name, but the generic term for the type of cement used in virtually all concrete, just as stainless is a type of steel and sterling a type of silver. Cement is manufactured by heating lime, silica, alumina, iron, and other materials at high temperature. The resulting substance is a marble-like ball called clinker that is ground, mixed with limestone and gypsum, and used to create concrete.

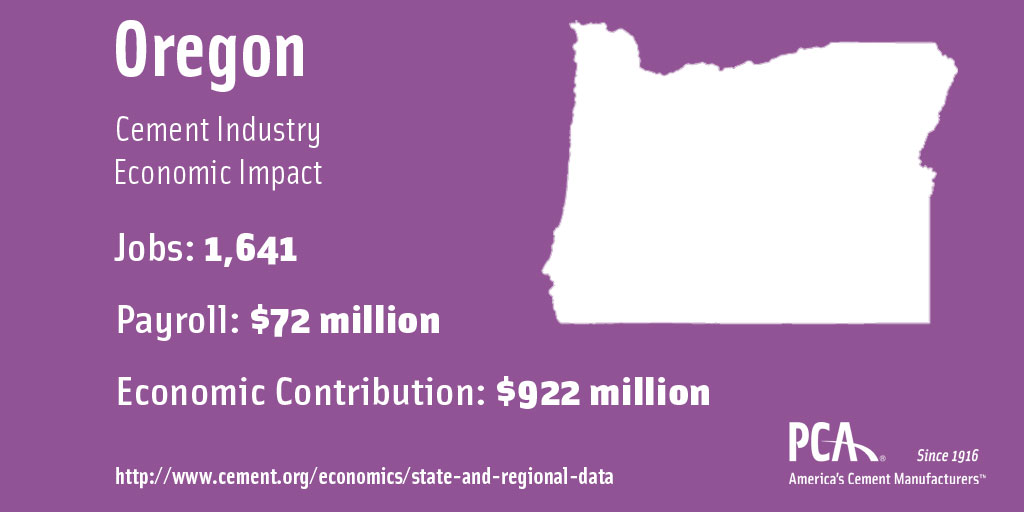

Building the Foundation of Oregon’s Economy — State Economic Data

- Clinker capacity: 1.0 million metric tons

- Cement consumption: 0.8 million metric tons U.S. Economic Data

- Clinker capacity: 101.3 million metric tons • Cement consumption: 94.4 million metric tons

- U.S. cement companies have annual sales valued at approximately $10.7 billion

Portland Cement Manufacturing and Use

- Portland Cement Association (PCA) represents 92% of US cement manufacturing capacity with over 90 plants in 32 states and distribution facilities in every state in the continental U.S.

- Cement and concrete product manufacturing directly or indirectly employs approximately 500,000 people in our country, and our collective industries contribute approximately $100 billion to our economy.

Energy and Environment

The U.S. cement industry has long been committed to minimizing emissions, waste, energy consumption, and the use of virgin raw materials. For example, the cement industry began to address climate change in the mid-1990s—one of the first industries to do so. Over the past 40 years, U.S. cement manufacturers have reduced the amount of energy required to produce a ton of cement by over 40 percent. The industry also has reduced its use of traditional fossil fuels by over 15 percent.

Occupational Health and Safety

Occupational Health and Safety

PCA members place the safety of their employees among their core values. The industry’s commitment to safety contributed to the Federal government’s recognition of 2015 as the safest year on record for Metal and Nonmetal miners, which includes our industry.

Transportation/Infrastructure

A well-functioning transportation network is the backbone of the U.S. economy and essential for U.S. businesses to compete globally and provide the best value to American consumers. Our nation’s core infrastructure should not only be maintained but also continuously expanded and improved to meet the needs of its citizens. Portland cement is an essential construction material and is uniquely positioned for the rebuilding of American infrastructure.

Benefits to Building with Concrete/Concrete Attributes

The American economy works most efficiently when guided by the market, while taking important public policy considerations, like safety, into consideration. Building owners, builders, architects, and designers have come to recognize that durable concrete public buildings, private homes, and businesses resist damage from natural disasters and reduce the impact entire communities have on our planet. Studies by MIT have shown that homes with concrete walls can use 8 to 15 percent less energy than other homes.

Sustainability and Resiliency

The industry is also a leader in sustainable material use and management, including reuse of industrial products as ingredients to make cement. Cement manufacturers often use alternative raw materials from industrial byproducts, such as those from coal combustion, steel blast furnace slag, and silica fume, keeping a large portion of these materials from being disposed of in landfills. The durability and resiliency of cement-related products also lower our environmental footprint. Concrete does not rust, rot, or burn, saving energy and resources needed to replace or repair damaged buildings and infrastructure.

- Because of its rigidity, concrete pavement can enhance the fuel efficiency of vehicles that travel on roads when compared to other pavements. If concrete pavements were used by the U.S. road system, fuel consumption is estimated to decrease by 3 percent nationwide, equating to a reduction in fuel consumption of 273 million barrels of crude oil a year, and a corresponding reduction decrease of greenhouse gas emissions by 51.2 million short tons.

- The energy efficiency of buildings also improves when concrete is used. A concrete construction home has been demonstrated to require 6-12 percent less energy than code-compliant wood frame construction.

![]()