The National Ready Mixed Concrete Association (NRMCA) has taken a significant step forward in helping the building industry to reduce the embodied carbon of the built environment.

It has developed a Concrete Carbon Calculator that provides a simple and efficient way for ready-mix suppliers and contractors to calculate the environmental impacts of concrete used in their building projects.

First launched in 2024, the tool has quickly become foundational in advocating for sustainable benefits and capabilities of concrete materials. It also helps to assess the impact of lower-carbon alternatives and demonstrates compliance with a pre-determined carbon budget on individual projects.

Developers and designers can also use this tool to establish regionally appropriate project carbon budgets to reduce embodied carbon on building and paving projects.

How the Tool Works

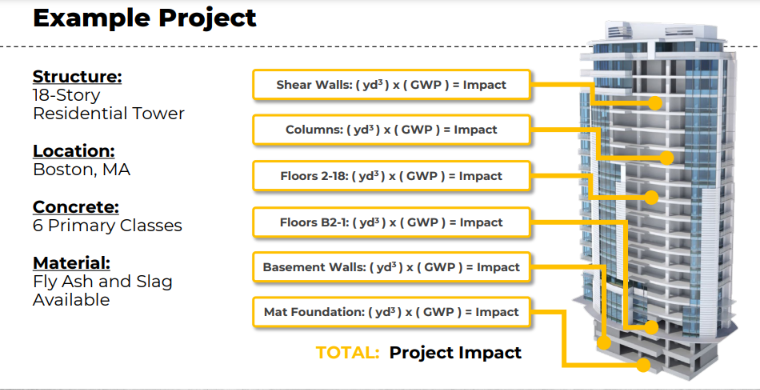

NRMCA’s Carbon Tool automatically populates benchmark impacts of a structure and calculates the estimated carbon sequestration of concrete throughout the structure’s life cycle. It then generates a report documenting a low-carbon concrete project’s anticipated carbon reduction potential compared to original benchmarks.

Using carbon footprint data from appropriate Environmental Product Declarations (EPDs), a structure’s overall carbon footprint can be calculated by entering concrete mix designs for the proposed project. It establishes a carbon budget and writes a specification that allows for the lowest possible carbon footprint.

What is a Carbon Budget?

A carbon budget is a concept that helps set emissions reduction targets for a given project. The NRMCA Concrete LCA and Project Budgeting Tool allows the contractor and producer to adjust concrete mixes to fit material, environmental, and schedule demands.

This helps reduce embodied carbon in building and paving projects and enables collaboration on projects that do not exceed embodied carbon reduction goals.

Concrete is unique among building materials. Its formulation is highly influenced by its application. Design professionals and contractors have a more significant influence on concrete formulation than on other building products.

Depending on performance needs, concrete can be made stronger, lighter, more flowable, stiffer, less permeable, and even weaker. Designers, contractors, and concrete producers can collaborate to reduce concrete’s carbon footprint.

Where to Find the Concrete Carbon Tool

NRMCA’s Build With Strength team has been promoting the tool and utilizing it as a consulting resource with design teams as they work towards reducing, quantifying, and specifying low-carbon concrete throughout the country. An easy-to-read Guide on how to use the Concrete Carbon Calculator is available here.

The NRMCA sustainability page has been updated to offer supportive resources for using the tool in an on-demand and downloadable format. Use the NRMCA Carbon Calculator here.

Updates include a 30-minute video presentation by Build With Strength’s Senior Director, Building Innovations, Brandon Wray, on carbon reduction strategies and how to use NRMCA’s Concrete Carbon Tool and LCA for Ready Mixed Concrete Report. Check out this exceptional video here.

READ MORE ON READY-MIXED CONCRETE INDUSTRY INITIATIVES TO DISCLOSE THE ENVIRONMENTAL IMPACTS OF PRODUCTS

Additional Resources

An excellent guide on measures to reduce building projects’ carbon footprint is available here: Climate Action What You Can Do Right Now (PDF).

AdditionalNRMCA Resources available to Project Designers and Contractors include:

-

Guide to Improving Specifications for Ready Mixed Concrete with Notes on Reducing Embodied Carbon Footprint, NRMCA Publication 2PE004‐21c, 2021. www.nrmca.org/sustainability

-

NRMCA Member Industry-Average EPD for Ready Mixed Concrete NRMCA 2021. https://www.nrmca.org/wp-content/uploads/2022/03/NRMCA_EPDV3-2_20220301.pdf

-

A Cradle-to-Gate Life Cycle Assessment of Ready-Mixed Concrete Manufactured by NRMCA Members — Version 3.2. NRMCA 2021. https://www.nrmca.org/wp-content/uploads/2022/02/NRMCA_LCAReportV3-2_20220224.pdf.

-

Possan, E. F. Felix, W. A. Thomaz, CO2 uptake by concrete carbonation during the life cycle of building structures, Springer International Publishing, Switzerland, October 2016.

-

Engage the Concrete Design Center for help with sustainable concrete design and specifications, www.buildwithstrength.com/design-center. Learn about the latest concrete innovations at www.concreteinnovations.com.

![]()